One-Way Valve

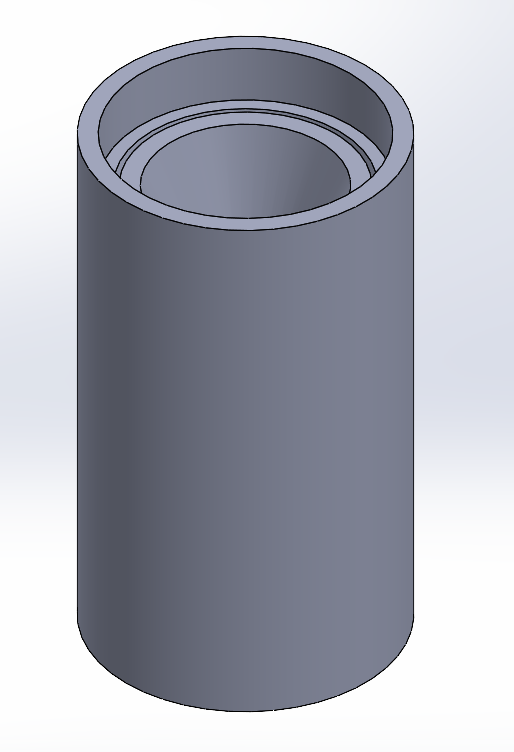

This project focused on the design and development of a functional one-way valve specifically optimized for 3D printing. The objective was to create a compact, reliable component that allows fluid flow in one direction while preventing backflow, using only additively manufactured parts.

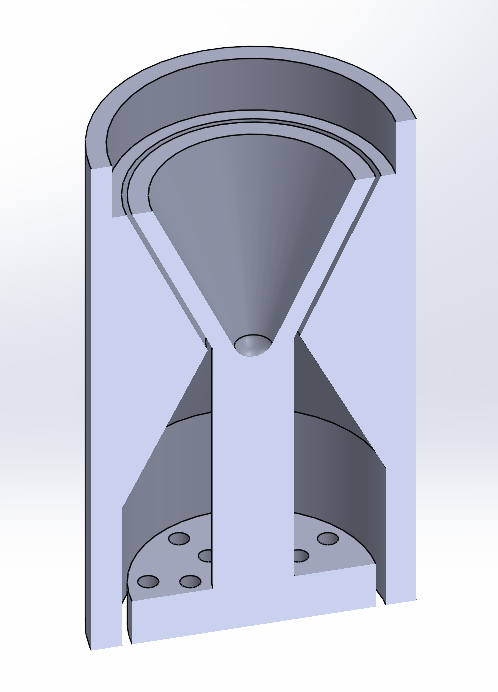

The design process began with researching different one-way valve mechanisms and evaluating their suitability for fused filament fabrication (FFF). Based on printability, assembly simplicity, and functional reliability, a flexible valve geometry was selected and adapted for additive manufacturing constraints such as layer orientation, tolerances, and material behavior.

The valve was modeled in CAD with careful consideration of wall thickness, sealing surfaces, and internal clearances to ensure proper operation without post-processing or additional hardware. Multiple design iterations were developed to improve flow efficiency and minimize leakage. The final design was successfully 3D printed and tested, demonstrating effective one-directional flow and consistent performance.

This project strengthened my skills in design for additive manufacturing (DfAM), functional prototyping, and iterative engineering design, while highlighting the importance of aligning mechanical functionality with manufacturing constraints.