DFAM Pneumatic Pump

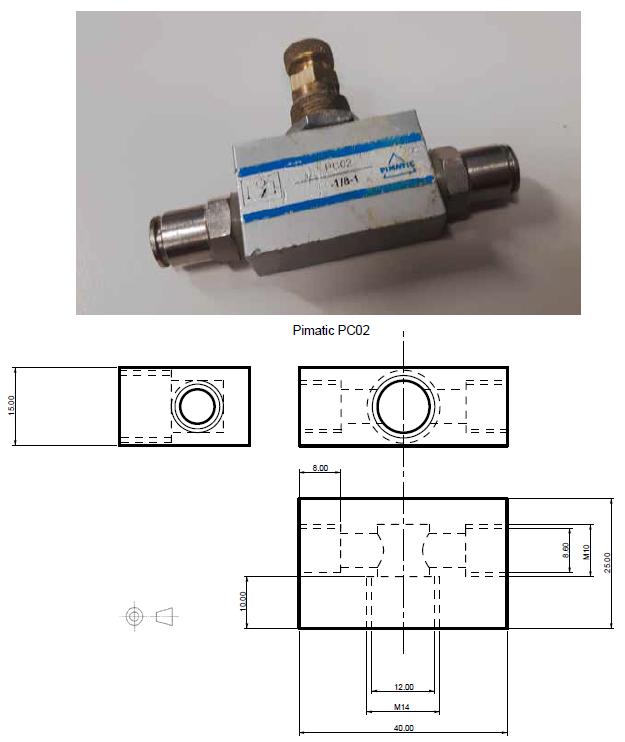

This project was an individual Design for Additive Manufacturing (DfAM) assignment focused on redesigning a pneumatic block for production using fused deposition modeling (FDM). The goal was to adapt an existing, conventionally manufactured pneumatic component for additive manufacturing while meeting strict geometric, functional, and manufacturing constraints.

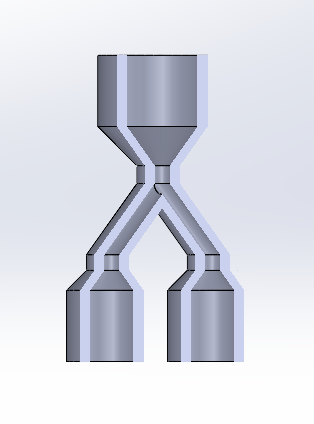

The original pneumatic block was analyzed based on the provided images and technical drawings. The component was modeled directly using the provided millimeter-based dimensions, with internal air channels and connection ports accurately reconstructed in CAD. To ensure printability, all threaded ports were redesigned as small-diameter round holes, respecting a minimum wall thickness of 2 mm and a minimum spacing of 8 mm between non-threaded holes.

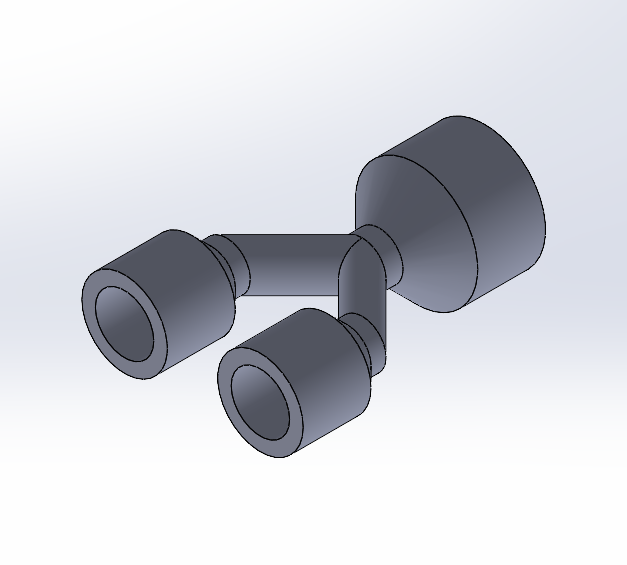

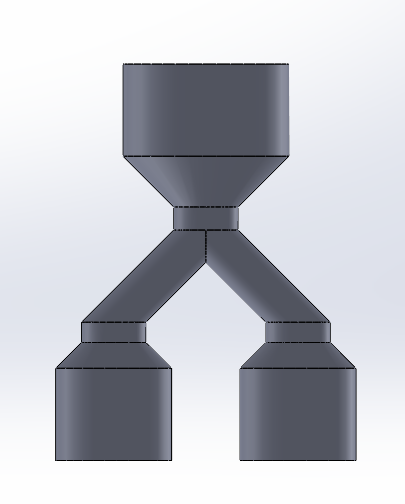

The design was optimized specifically for FDM without the use of support structures. This required careful consideration of internal channel geometry, overhang angles, and printing orientation. The internal flow paths were modified to maintain pneumatic functionality while ensuring manufacturability and structural integrity. Material usage and print time were minimized through compact geometry and efficient wall design.

The final result was a fully printable pneumatic block model, exported as a high-resolution STL file in the optimal printing orientation. This project demonstrates a strong understanding of additive manufacturing constraints, functional redesign, and the translation of traditional mechanical components into optimized 3D-printable parts.