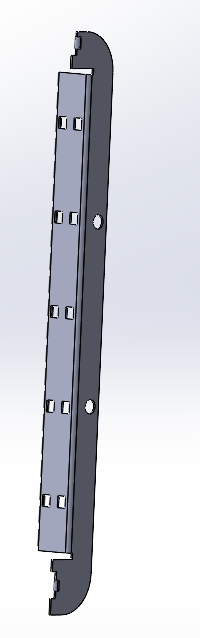

Sheet Metal Parts

As part of the reverse engineering project, I was tasked with reconstructing two sheet metal components of a heat pump tumble dryer. The provided 3D scan data lacked a proper coordinate system and contained missing edges, which required additional preparation before modeling.

I established a defined coordinate system in SolidWorks, realigned the scans, and used sketches to trace the geometry of the parts. Using the Sheet Metal module, I recreated the components with a uniform thickness of 1 mm. The modeling process involved applying key features such as base flanges, edge flanges, extruded cuts, hems, fillets, folds/unfolds, and flat patterns. Special consideration was given to bend allowance, bend deduction, and the K-Factor, ensuring the models accurately represented real-world manufacturable parts.

This task enhanced my ability to work with incomplete scan data, develop parametric sheet metal models, and apply practical manufacturing parameters to digital prototypes. The final parts were validated through flat pattern generation, confirming their feasibility for fabrication.