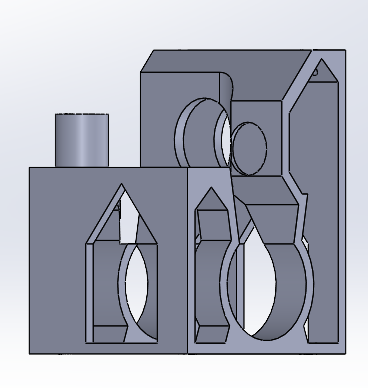

Part Integration

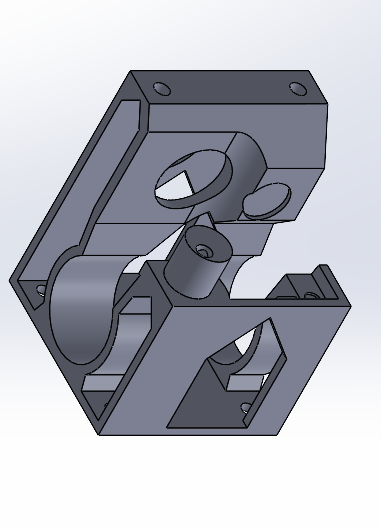

The goal of this project was to take a traditional multi-part mechanical assembly—originally designed for subtractive manufacturing (CNC machining) and standard hardware—and redesign it as a single, unified component optimized for 3D printing. This process, known as Part Consolidation, focuses on reducing assembly time, eliminating mechanical fasteners, and optimizing material distribution without compromising the functional integrity of the assembly.

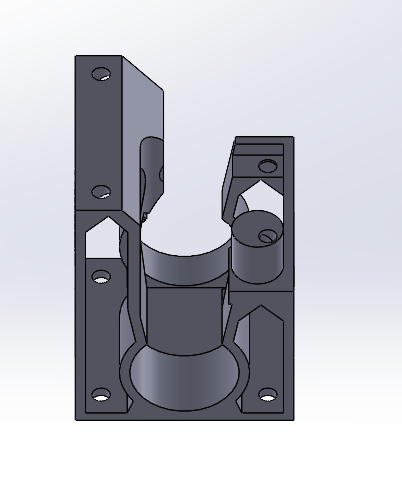

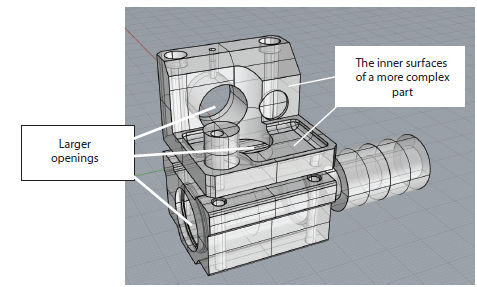

The redesign was guided by several critical engineering constraints to ensure the new part remained compatible with existing hardware like linear bearings and shafts:

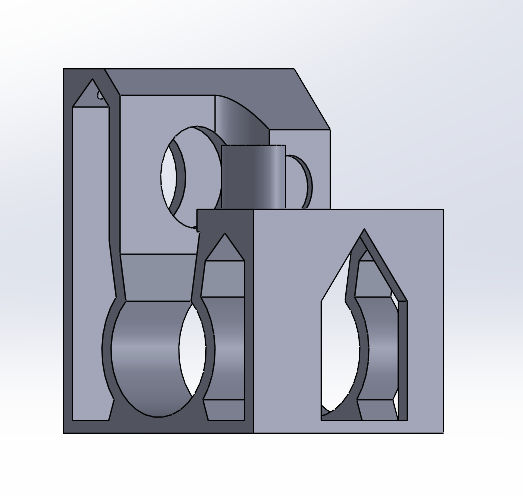

Functional Surface Retention: The "inner surfaces" and "larger openings" (critical for bearing fitment and shaft clearance) had to remain dimensionally exact.

Geometric Orientation: The original axial alignment of the openings had to be preserved to ensure the mechanical system functioned as intended.

Part Integration: The two separate machined housings and the fastening hardware (screws and clips) were combined into one seamless body.

Hardware Exclusion: While the bearing and fasteners guided the geometry, they were not modeled in the final print file, focusing strictly on the monolithic housing.